LM40UU LINEAR BEARING

LM40UU LINEAR BEARING Specification

- Precision Rating

- ABEC-3

- Cage Material

- Polyamide

- Lubrication Type

- Grease Lubrication

- Inside Diameter

- 40 mm

- Thickness

- 80 mm

- Retainer

- Steel Retainer

- Usage

- Industrial

- Bearing Type

- Ball Bearing

- Material

- Stainless Steel

- Size

- Standard

- Structure

- Linear Ball Bearing

- Product Type

- Ball Bearing

- Seals Type

- Double Sealed

- Number Of Rows

- Single Row

- Bore Size

- 40 mm

- Color

- Silver

- Outside Diameter

- 60 mm

- Limiting Speed

- 3800 RPM

- Load Capacity

- Heavy Duty

- Compatible Shaft Diameter

- 40 mm

- Temperature Range

- -20°C to 80°C

- Tolerance

- +0/-0.010 mm

- Dynamic Load Rating

- 5200 N

- Application

- Automation Equipment, CNC Machinery, Linear Motion Systems

- Surface Treatment

- Corrosion Resistant

- Static Load Rating

- 7800 N

- Mounting Method

- Press Fit

LM40UU LINEAR BEARING Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 7 Days

About LM40UU LINEAR BEARING

Linear bearings facilitate smooth, low-friction motion along a straight path, vital in various applications like manufacturing, automation, and robotics. They come in various types, including ball, roller, and plain bearings, each offering unique benefits.A ball screw is a mechanical linear actuator that converts rotational motion to linear motion with minimal friction by using a threaded shaft and a nut housing balls that roll between them, offering high precision and efficiency.

Optimized for Industrial Precision

Built with high-grade stainless steel and a steel retainer, the LM40UU linear bearing boasts a sturdy, corrosion-resistant design suitable for demanding industrial environments. Featuring tight tolerance (+0/-0.010 mm) and an ABEC-3 precision rating, this bearing assures smooth and accurate motion in every application.

Versatile Applications and Reliable Performance

Ideal for integration into automation equipment, CNC machinery, and diverse linear motion systems, the LM40UU supports heavy-duty loads while maintaining precision. Its press-fit mounting method ensures easy installation, and double seals offer protection against contaminants for extended operational life.

FAQ's of LM40UU LINEAR BEARING:

Q: How should the LM40UU Linear Bearing be installed?

A: The LM40UU Linear Bearing is designed for press-fit mounting into compatible housings. Ensure that the housing bore matches the bearing's outside diameter (60 mm) with the specified tolerance. Gently press the bearing into place using an appropriate tool to prevent deformation or damage.Q: What are the benefits of the corrosion-resistant surface treatment on this bearing?

A: The corrosion-resistant surface treatment enhances durability by protecting the stainless steel body from rust and oxidation, ensuring reliable operation even in moisture-prone industrial environments.Q: Where can the LM40UU Linear Bearing be used?

A: This linear bearing is suitable for a wide range of applications, including automation equipment, CNC machines, and linear motion systems. Its robust design and high load ratings make it ideal for use in industrial settings where precision and reliability are critical.Q: When is it necessary to relubricate the bearing?

A: Periodic relubrication is recommended based on operating conditions, such as load intensity and speed. Grease lubrication is preferred, and schedules should follow equipment manufacturer guidelines or be adjusted based on observed performance.Q: What is the compatible shaft diameter for the LM40UU Linear Bearing?

A: The bearing is specifically designed to fit a shaft diameter of 40 mm, ensuring optimal alignment, support, and operational efficiency.Q: How does the double-sealed design contribute to the bearing's performance?

A: The double-sealed configuration effectively keeps out dust and contaminants, maintaining internal lubrication and extending the bearing's service life even in harsh conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

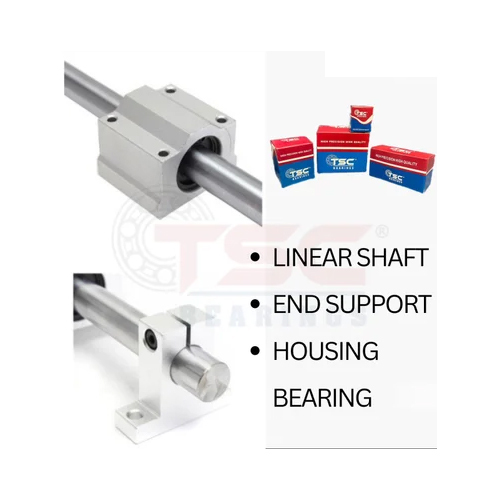

More Products in Ball Bearing Category

Linear Guides

Minimum Order Quantity : 100 Pieces

Size : Standard

Material : Stainless Steel

Product Type : Linear Guides

Color : Silver

TSC K005 PILLOW BLOCK SERIES

Price 180.0 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard Sizes

Material : Stainless Steel

Product Type : Pillow Blocks

Color : Silver

TSC KP007 PILLOW BLOCK SERIES

Price 240.0 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard Sizes

Material : Stainless Steel

Product Type : Pillow Block

Color : Silver

TSC K001 PILLOW BLOCK SERIES

Price 120.0 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard Sizes

Material : Stainless Steel

Product Type : Pillow Block

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry